A cikin fasahar nuna lantarki ta zamani, ana amfani da allon LED sosai a madadin dijital, kayan ado na gida da sauran filaye saboda babban haske, mai girma, rayuwa tsawon rai da sauran fa'idodi. A cikin masana'antar da aka tsara na LED, fasahar Enginita shine hanyar haɗi. Daga gare su, fasahar ta hanyar smd da fasahar cob na cob sune mahaɗan babban zango guda biyu. To, menene bambanci tsakanin su? Wannan labarin zai samar maka da bincike mai zurfi.

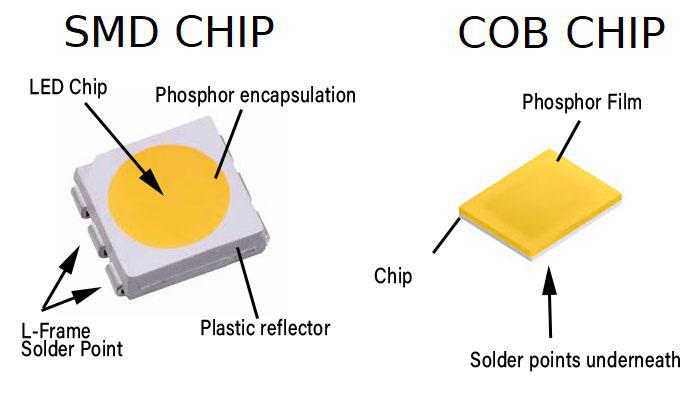

1.Wannan fasahar conta ce ta SMD, Ka'idodin Copaging

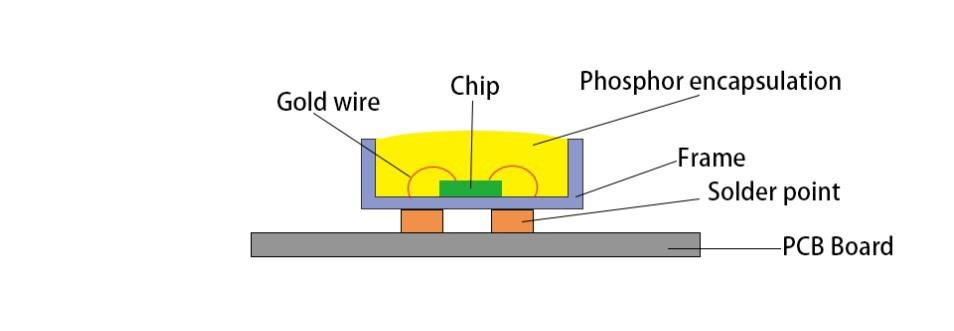

Kunshin SMD, Na'urar Cikakken Na'ur (Na'urar Dutse), watau irin kayan lantarki ne kai tsaye da welded ga buga fasahar kewaye. Wannan fasaha ta hanyar injin da aka yi daidai, chipapsulated chipits (galibi yana dauke da abubuwan haɗin da suka dace da wasu hanyoyi don gane hanyar lantarki da sauran hanyoyin da za a sanya su Fasaha yana sa kayan haɗin lantarki suna sa karami, mai haske cikin nauyi, kuma yana ba da damar ƙirar ƙarin samfuran ƙarin wadataccen abu.

2. Sha'ayoyi fa'idodi da rashin amfani da fasahar conce

2.1 SMD contaging Fasaha Fastaging

(1)Sizearamin girma, nauyi nauyi:Abubuwan da aka haɗa masu kunnawa SMD suna ƙanana da girma, da sauƙin haɗa manyan-iri-iri, masu dacewa da ƙirar minamurized da samfuran lantarki.

(2)halaye masu kyau na mita:Short gajerunannun da gajerun hanyoyin sadarwa suna taimakawa rage aiwatarwa da juriya, inganta babban-mitar.

(3)Dace don samar da atomatik:Ya dace da samar da injin sarrafa kansa, inganta haɓakar samarwa da kwanciyar hankali mai inganci.

(4)Kyakkyawan aikin zafi:Tuntushin kai tsaye tare da PCB surface, mai dacewa ga diski mai zafi.

2.2 SMD concefing Fasahar Fasaha

(1)Daidai hadaddun tabbatarwa: Kodayake hanya mai hawa ta saman ta sa ya zama mafi sauƙaƙa gyara da maye gurbin hadewar abubuwa masu yawa, wanda zai maye gurbin mutum abubuwan da aka saƙa na iya zama mafi cumbersome.

(2)Limitarancin Yankin Lafiya Lafiya:Ainihin ta cikin kushin da gel dissive dissipation, dogon lokaci aiki na iya haifar da bugun zafi, wanda ya shafi rayuwar sabis.

3.Wanar fasahar cob mai kwakwalwa, ka'idodin tattarawa

COB kunshin, da aka sani da guntu a kan jirgin (Chip a kan kunshin katako), ƙayyadadden guntu), shine guntu kai tsaye a kan fasahar contiging fasaha. Tsarin tsari shine guntu guntu (guntu jiki jiki da i / o filaye na crystal sama) tare da m adhehedive zuwa PCB, sannan ta waya ko kuma waya ta zinariya) a cikin aikin na matsanancin zafi, da guntu na i / o filals da pcb na an haɗa shi, kuma a karshe an rufe su da resin ari kariya. Wannan alingin yana kawar da yanayin ciyawar Gilashin Ginin Lantarki ta LED ta hanyar Expapsulation na gargajiya, yana yin kunshin mayaci.

4.Da taimako da rashin amfanin fasahar cob

4.1 cob contaging Fasaha

(1) Kunshin masarufi, ƙananan girman:Cire filayen filayen, don cimma matsakaicin sikelin.

(2) kyakkyawan aiki:Waya ta zinare tana haɗa guntu da jirgin da ke da'irar, nesa mai watsa siginar sigina yana gajarta, rage crossalk da kuma sauran batutuwa don inganta aiki.

(3) Kyakkyawan zafi mai zafi:Ana bushe guntu kai tsaye zuwa PCB, da zafi kuma an watse ta hanyar duka hukumar PCB, kuma zafi yana cikin sauƙin watsawa.

(4) aikin kariya mai ƙarfi:Kyakkyawan ƙirar da aka rufe, tare da mai hana ruwa, danshi-hujja, danshi-hujja, anti-static da sauran ayyukan kariya.

(5) Kwarewar gani mai kyau:A matsayin tushen hasken saman, aikin launi ya fi zama bayyanannu, dacewa da kyakkyawan aiki, dace da dogon lokaci kallon kallo.

4.2 Cob contaging Fasahar Fasaha

(1) wahalar kulawa:Chip da PCB kai tsaye waldi, ba za a iya watsa daban ko maye gurbin guntu ba, farashin kiyayewa suna da yawa.

(2) mai tsayayyen bukatun kayan aiki:Tsarin mai ɗorewa na buƙatun bukatun muhalli suna da yawa sosai, baya barin ƙura, yana tsaye wutar lantarki da sauran abubuwan da aka lalata.

5. Bambanci tsakanin fasahar cocaging da fasahar cob

Fasahar ta SMD ta SMD da fasaha ta COB a fagen nuna halaye kowannensu yana da nasa fasikinsa na musamman, girma da nauyi, canji tsakanin su da kyau da yanayin kulawa da yanayin zafi. Mai zuwa cikakken bayani ne da bincike:

5.1 hanya ce

Fasaha ta Fasaha: Cikakken suna shi ne na'urar da aka ɗora, wacce keke fage da siyar da chipt chiquit jirgin ruwa (PCB) ta hanyar injin patch. Wannan hanyar tana buƙatar chip na LED a gaba don samar da kayan aiki mai zaman kansu sannan ya hau kan PCB.

Fasaha na Fasaha Fasaha: Cikakken suna shine guntu a kan allo, wanda shine fasahar marufi wanda ke siyar da guntun guntu akan PCB. Yana kawar da matakan shirya fitilar LED na gargajiya na gargajiya, kai tsaye a kan gonar da ke ciki kai tsaye, kuma ya fahimci haɗin lantarki ta hanyar ƙarfe.

5.2 Girman da nauyi

Packagari na ⑴smd: Kodayake abubuwan haɗin suna ƙanana ne, girman su da nauyinsu har yanzu suna iyakance saboda tsarin tattarawa da buƙatun tattarawa da bukatun tattara.

Fakitin Botob: Saboda tsallake filayen filayen filaye da harsashi mai kunshin, kunshin cob ya cim ma hadari hadari, yana yin kunshin karami da sauƙi.

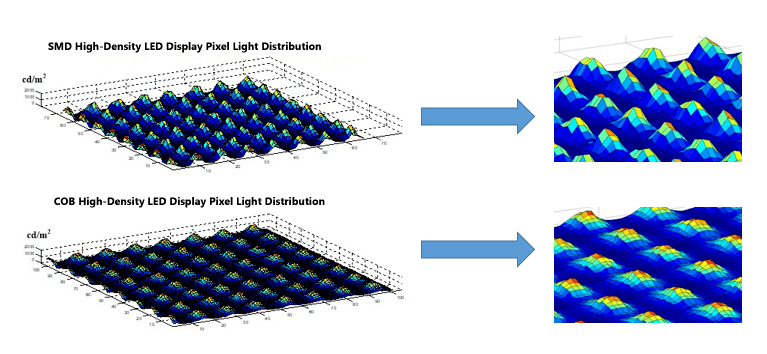

5.3 Haske Downationation

Packaging na ⑴smd: galibi watsar da zafi ta hanyar rufaffukai, kuma yanki mai zafi yana da iyaka. A karkashin babban haske da yanayi mai yawa, zafi yana iya zama mai da hankali a cikin yanki yanki, shafi rayuwa da kwanciyar hankali nuni.

Fakitin Vebeb: Chip an kunna kai tsaye akan PCB da zafi za a iya watsa ta cikin duka hukumomin PCB. Wannan ƙirar tana inganta aikin zafi na nuni da rage darajar gazawa saboda yawan zafi.

5.4 Saukakewa na Gwaji

Packagari na ⑴smd: tunda an sanya kayan haɗin kai daban akan PCB, yana da sauƙin maye gurbin guda ɗaya yayin kulawa. Wannan yana da dacewa don rage farashin kiyayewa da kuma gajeriyar lokacin kiyayewa.

Kabilar Vebob: tunda Chip da PCB ana welded kai tsaye zuwa duka, ba shi yiwuwa a watsa ko maye gurbin guntu daban. Da zarar kuskure ya faru, yawanci ya zama dole don maye gurbin gaba ɗaya kwamitin ko dawo da shi zuwa masana'antar don gyara, wanda ke ƙaruwa da farashi da wahala gyara.

Fattarar Aikace-aikace 5.5

Focaging Packaging: Saboda babban balaga da ƙarancin farashi, ana amfani dashi a cikin kasuwa, musamman ma a cikin ayyukan ingantacce kuma suna buƙatar takaddun tabbatarwa na waje da ganuwar waje da bangon TV na cikin gida.

Wagesewararrun cocobe: Saboda babban aikinta da babban kariya, ya fi dacewa da hotunan allo na cikin gida, ɗakunan ajiya da sauran abubuwan da ke da buƙatu masu inganci. Misali, a cikin cibiyoyin umarni, studios, manyan mukaman kulawa da wasu ma'aikata suna kallon allo na dogon lokaci, fasahar Cob mai amfani na iya samar da ƙwarewar gani da kuma suturar gani.

Ƙarshe

Fasaha ta SMD da fasahar cobd da fasahar cob kowannensu suna da nasu ingantacciyar fa'idodinsu na musamman a fagen hotunan allo. Masu amfani yakamata su riƙi, suka zaɓi gwargwadon bukatun ainihin lokacin zabar.

Fasaha na SMD mai fasali da fasahar cob da cobar cobagging suna da nasu fa'idodinsu. Ana amfani da fasahar capta na SMD sosai a kasuwa saboda yawan balaguronsa saboda yawan balaguronsa da ƙarancin farashi, musamman a cikin ayyukan da suke da mahimmanci da kuma buƙatun mai mahimmanci. Fasahar Cob, a gefe guda, yana da gasa mai ƙarfi a cikin Hannun Nunin Innoor, ɗakunan ajiya, kyakkyawan aiki tare da aikin Kariya mai ƙarfi.

Lokacin Post: Sat-20-2024